RTM向LRTM的过渡

可以说,LRTM现在已经在世界各地成为主流闭模工艺,尽管新RTM项目仍在实施,但无法改变其渐渐淡出的趋势。原因很简单,LRTM可以用仅占RTM三分之一的时间成本和三分之一的生产成本,制备出专业性强,尺寸精确的闭模制件。当然我们更不能忽视,如果在相同的生产经营基础上,LRTM比RTM需要安装更少的基础设施,和具备均匀化合理化的成本投入。

过去,人们常认为LRTM仅限于制备相对简单和规模小的零件,但事实已经证明,LRTM同样可以制造部分形状复杂,甚至夹金属或泡沫芯的制件。即使纤维量高达55-62%的复合材料部件也可以利用LRTM成型工艺完成制备,而且单组分树脂体系的注射和固化温度只需要分别达到80℃和180℃即可。

此外,制件的规模也基本不受限制,LRTM已经广泛用于造船业就是一个最好的佐证。法国造船商Jeanneau已经采用LRTM工艺超过6年了,现在用这种工艺能注射出长达142英尺且外形复杂的游艇甲板。目前,该公司还在继续投资,以图进一步将该工艺推广到全部船体部件的制造上。

几年前推出了一种多层插入模具技术(Multiple Insert Tooling technology - MIT),即将RTM的A模插入多层副模。当其中一层被注射树脂时,另一层还可以做凝胶用,剩下的一层用来铺设玻璃纤维。这可能会大大增加一套模具设备的生产量,从而缩短生产周期,要知道生产周期是决定制件注射和固化速度的唯一因素。在压制过程中,可以迅速调整预加载层的位置,以保证能马上投入新的注射周期。但是,随着LRTM工艺开始流行,人们看到LRTM工艺可以像MIT一样实现低成本量产,最主要的是人们不再需要昂贵的模压设备。

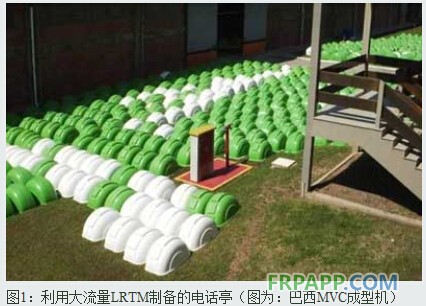

一台装备了多个LRTM模具的巴西MVC成型机每天实际生产650件表面积达到1.5平方米的胶衣涂层制品,多模LRTM的制备效率由此可见一斑。如今,LRTM设备生产商纷纷鼓励他们的用户至少用两个A模配一个B模的方式以使生产效率翻番,而成本却只需要增加三分之一。

投资气动控制注射系统(pneumatically - controlled injection system)成为近年来的一种趋势。例如,纯气动PneuJect III注塑机模型,可提供可编程的催化剂增加控制,自动冲洗和催化剂流量报警,精密注塑压力/流量控制,催化剂/溶剂水平控制和警报功能。所有这些功能的实现不需要任何电器辅助,很适合玻璃钢车间环境。而纯气动设备需要气动压力/真空传感器(PPVS)的配合,即通过它感知LRTM模内的注塑压力,因此达到安全控制设备的产出水平的目的。

气动设备的引入也推动着气动压力传感器朝着更智能化的方向发展,用户可以根据设置通过它准确感知树脂是否充满模腔。原理是通过传感器向设备发送信号,来控制树脂注射的进程,因此大大节省了操作者的劳力,和降低了人力估计的不准确因素。此外,传感器还可以在无操作员介入的条件下,通过发送关闭信号实现对大型模具多个真空排气口的自动控制。需要注意的一点是,这些纯气动设备都必须从头开始设计,因为在目前的市场上没有相当的设备。

英文原文:

Reinforced Plastics: Where is the LRTM process currently being used?

Alan Harper: It would be safe to say that LRTM is now the mainstream closed mould method throughout the world and although new RTM projects are still being applied, they tend to be in a minority. The simple reason is that LRTM tooling can be manufactured in one-third of the time at one-third of the cost yet still deliver a professional, accurate, closed mould part. We must also not forget that LRTM requires far less infrastructure installation and cost amortised over similar RTM type production runs.

Reinforced Plastics: What types of part can LRTM be used for?

Alan Harper: It used to be said that LRTM was limited to relatively simple, small parts, however shistory has shown that parts with complex undercuts, metal, foam and all manner of inserts are now produced by LRTM. Even high fibre volume (55-62%) composite parts are moulded by the LRTM technology using single component resin systems injected at 80°C and needing curing at 180°C.

Size of part is also not restricted as can be seen in the boat industry. An excellent example is boat builder Jeanneau in France who have been injecting a 42 ft complex yacht deck by LRTM for over six years now and continue to invest in closed mould production for all their hulls.

Reinforced Plastics: What volumes of parts is LRTM suitable for?

Alan Harper: Some years ago we introduced a Multiple Insert Tooling technology called MIT whereby an RTM ‘A’ face composite mould had multiple mould replicas in the form of insert skins. While one was being injected, another could be gel-coated, and a third have the glass loaded. This brought about a serious increase in potential output from one production tool set and was heralded as the answer to speeding up cycle times as the only governing factor was how quickly the part could be injected and cured. Pre-loaded MIT skins were rapidly interchanged in the press allowing instant start of new injection cycle.

Once the LRTM process became popular we saw that multiple 'A' face LRTM moulds could be produced just as economically as the MIT skin so similar higher production runs could be realised economically, especially as we no longer employed a costly mechanical press.

One Brazilian moulder, MVC, actually achieved the production of 1.5 m2 gel-coated parts at a rate of 650 per day using multiple LRTM mould sets, which demonstrates how versatile the system is.

Today, we often advise clients to produce at least two 'A' face tools to match one 'B' face back tool as this immediately provides potential for twice the daily moulding output, yet incurring only a third extra tool cost.

Current developments

Reinforced Plastics: MVP has just launched a pneumatically-controlled injection system. What where the reasons behind this?

Alan Harper: Naturally, equipment to inject moulds has continually developed over the years. Although there has been a trend by many to advance electronic control using PLC (Programable Logic Controllers), MVP have responded to the need by also developing a new form of PLC (Pneumatic Logic Control). The all air-powered PneuJect III injection machine model, for example, offers programmable catalyst increase, auto flush and catalyst flow alarm, precise injection pressure/flow control and catalyst and solvent level, alarms. All these features are provided without the need to employ any electrical hardware. This is, understandably, more acceptable in the FRP workshop environment.

Reinforced Plastics: What other equipment developments are being introduced?

Alan Harper: Again, moving away from any standard form of electrical mould pressure sensing it became apparent that there was a need for pure pneumatics. This led to the introduction of the Pneumatic Pressure/Vacuum Sensor (PPVS), whereby the injection pressure inside the LRTM mould is sensed and consequently safely controls the machine output levels.

A further pneumatic sensor development ensued, designed to sense the resin arriving at the mould final fill point or a final fill zone by user choice. This enables the mould to signal the machine when to stop injecting thus removing the need for the operator to best guess a pre-determined mould shot count. It is also available to automatically control multiple vacuum vents on large moulds by signalling shut down without operator involvement.

All of these pure pneumatic equipment developments had to be designed from scratch as there were no pneumatic equivalents in the market.

鲁ICP备2021047099号

鲁ICP备2021047099号